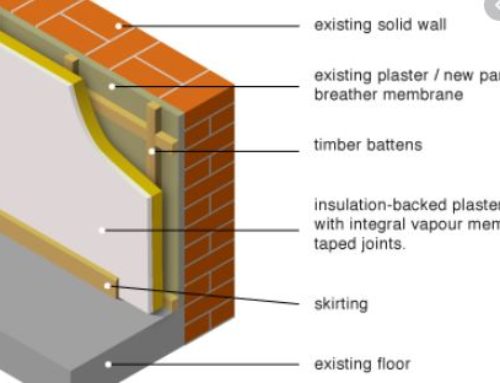

With the new Vancouver insulation requirements we also have to achieve the effective R22 below grade as well. This can be accomplished in several ways however the thinnest wall assembly to achieve this is also a split insulation wall like that above grade assembly mentioned earlier ( where 1 layer of the insulation runs continuous and then we utilize the stud cavities for the second layer) .

The standard below grade wall assembly in Vancouver in the past was a 2×6 furring wall stuffed with fiberglass batt insulation and 6 mil poly that acted as both a air barrier and vapour barrier. It is very important to understand the difference between the 2, the air barrier is a sealed barrier that stops airflow ( which vapour can travel in the air ) and a vapour barrier is simply a barrier that is continuous but does not need to be sealed as it only stops vapour molecules that are bouncing around the room, for example 2 sheets of poly that are overlapped make a vapour barrier but not a air barrier. The majority of vapour that exits or enters the building travels in the air and does not permeate (meaning the air barrier is FAR more important that the vapour barrier). So if we were only going to have 1 of them we would have the air barrier. However it is better to have both of them if done properly. The worst wall assembly we can create is one that has 2 vapour barriers inside the wall, the reason is that if any moisture enters this cavity it will be trapped and cause the growth of mold and mildew and could even rot the lumber inside the wall.

Although concrete is somewhat vapour permeable the traditional wall assembly with dimple membrane, 2 coats damproofing, 8″ concrete wall, 1/2 ” air gap, 2×6 furring, fiberglass insulation, 6 mil poly and gypsum board does not function that well and most cases being pulled apart as little as 5 years later you will observe mold growth in the wall which results in poor air quality in the basement. So now that we understand this we can select a better wall assembly that not only meets Vancouver’s requirements but also functions well for having a healthy home. One wall assembly we could choose is to put 2″ XPS insulation on the inside of the concrete wall in a continuous fashion, if we seal all of the joints this will act as both a air barrier and a vapour barrier, so the main thing to remember if we choose this is that we cannot have a second traditional vapour barrier in the assembly. This means that the foundation walls must be full height otherwise we would not be able to use the XPS as a air barrier. XPS is considered a vapour barrier if thicker than 1″ ( the exact thickness is somewhat up to debate ). Taping and sealing all joints is very important to achieve the new vancouver air tightness requirements which are now being tested so it is performance based requirement not a spec based requirement. If the foundation walls are not full height then it would be easier to not use the XPS as a air barrier but use a smart vapour barrier on the standard location between the furring studs and the gypsum, remember the xps will still not allow vapour to permeate and even if it does there is very little drying that will occur through the remainder of the assembly.

The smart barrier does not allow vapour to transfer through if there are lower levels of humidity ( like in a normal home ) however allows vapour to permeate through if there is high levels ( like water entering the cavity). So to clarify this below grades assembly proposed we are using dimple membrane, 2 coats damproofing, 8″ concrete wall. 2″ XPS insulation taped and sealed, 1/2 ” gap ( to allow for the furring wall to be straight, a gap between the batt insulation and the XPS is not required ), 2×4 furring wall, roxul insulation ( this performs better than batt insulation in the event there is any moisture in the wall assembly ), gypsum board, regular paint ( regular paint does allow vapour to permeate through ). The other option is to have the XPS not sealed ( or if it is not running continuous ) and use a smart vapour barrier between the furring wall and the gypsum board.

Leave A Comment